Karnataka Electronic Jacquard Scheme Guidelines - Summary

Karnataka Electronic Jacquard Scheme Guidelines: Empowering Weavers

The Karnataka Electronic Jacquard Scheme is a vital initiative aimed at supporting power loom weavers by enhancing their skills and promoting self-employment. With India producing only 5% of cloth through organized sectors, a significant 20% through handlooms, 15% through knitting, and a substantial 60% through decentralized power looms, this scheme plays a crucial role. In Karnataka, there are approximately 120,000 looms dedicated to weaving silk and cotton, mainly located in Belagavi, Bagalkote, Tumkur, and the Bangalore Urban and Rural Districts. 💡

Modernization and Support for Power Loom Weavers

The Karnataka State Textile Infrastructure Development Corporation (KSTIDC) is instrumental in modernizing the power loom sector. It has introduced several schemes, like the Weavers Special Package Scheme, that focus on the empowerment of power loom weavers. These initiatives aim to help weavers achieve self-employment and seamlessly integrate into mainstream society.

1. Supply of 02 Ordinary Power Looms & Accessories:

- Unit cost: Rs.3,00,000/-

- Subsidy (% age) for General: 50% or maximum Rs.1,50,000/- Beneficiary Contribution / Bank loan 50%

- Subsidy (% age) for SCs/STs: 90% or maximum Rs.2,70,000/- Beneficiary Contribution / Bank loan 10%

- How it helps: This provision is helpful for weavers to establish their own units and secure self-employment.

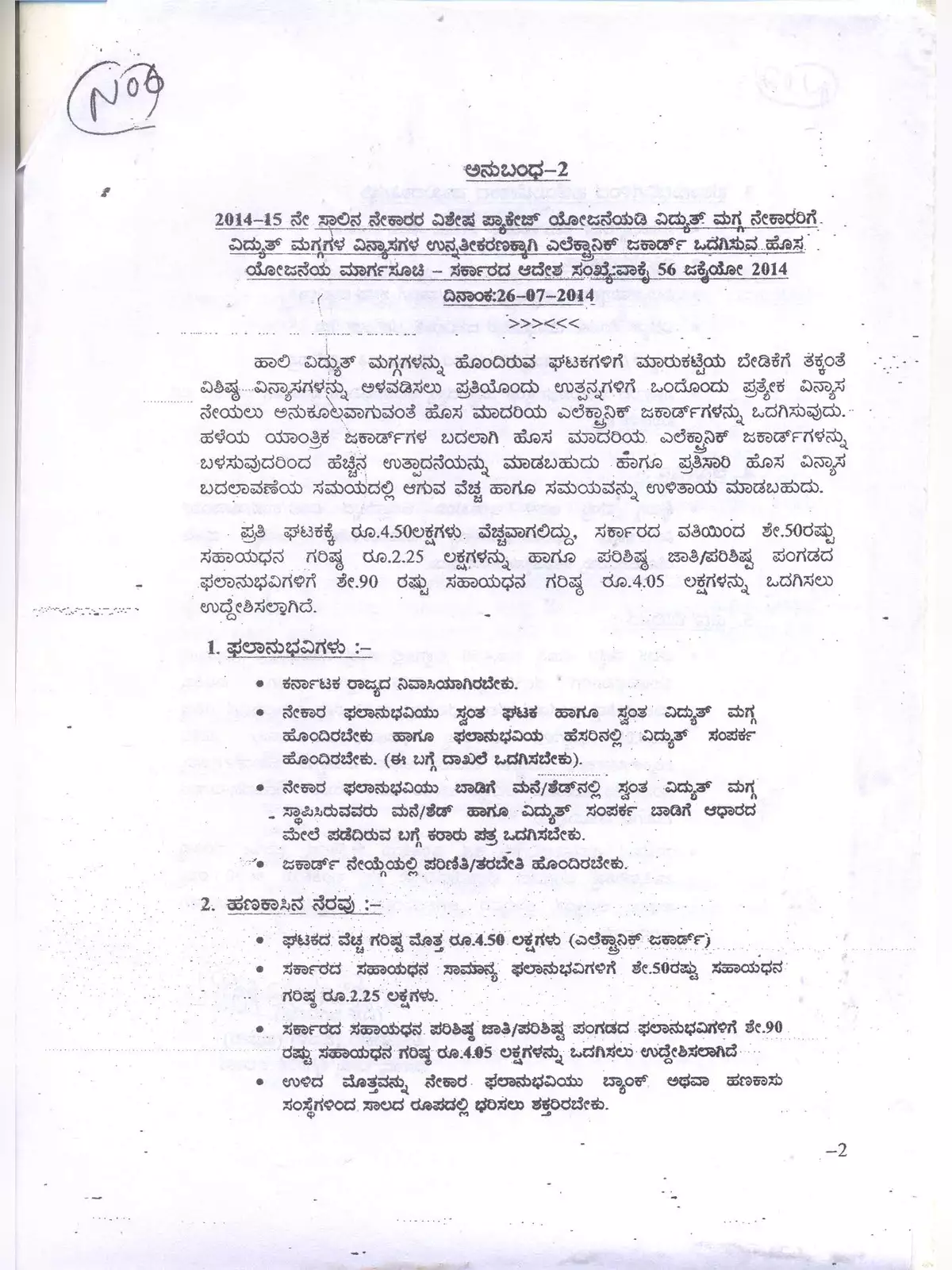

2. Electronic Jacquard:

The introduction of electronic jacquards in existing power loom industries is transforming the design process. This innovative solution eliminates the requirement for frequent mechanical adjustments, allowing weavers to create multiple designs at lower costs. This technology facilitates the production of distinctive designs for each saree.

- Unit cost: Rs.4,50,000/-

- Subsidy (% age) for General: 50% or maximum Rs.2,25,000/- Beneficiary Contribution / Bank loan 50%

- Subsidy (% age) for SCs/STs: 90% or maximum Rs.4,05,000/- Beneficiary Contribution / Bank loan 10%

- How it helps: This enables weavers to create varied designs, enhancing the value of their products.

3. Knotting Machine:

Traditionally, power loom industries relied on manual knotting for new warp beams, making the process lengthy. The introduction of knotting machines speeds up this task and improves efficiency, leading to continuous production.

- Unit cost: Rs.5,00,000/-

- Subsidy (% age) for General: 50% or maximum Rs.2,50,000/- Beneficiary Contribution / Bank loan 50%

- Subsidy (% age) for SCs/STs: 90% or maximum Rs.4,50,000/- Beneficiary Contribution / Bank loan 10%

- How it helps: This machine helps weavers complete knotting more quickly, ensuring uninterrupted production.

For detailed guidelines and further information about the Karnataka Electronic Jacquard Scheme, you can download the PDF now and keep it handy!

Don’t forget to download the PDF for all the essential details!